Sprayers of series “KA”

Universal application, optimal adaptation to vegetation.

Excellent surfacing with low wear due to targeted air supply, thus environmentally friendly and efficient.

Capacity:

- 1000 liters

- 1500 liters

- 2000 liters

Features

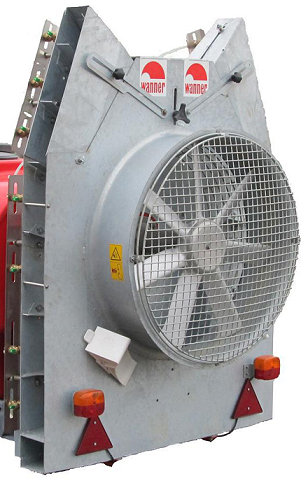

Air blower design

- Galvanized housing

- Low energy consumption and low noise due to special aerodynamic wing

- Centrifugal clutch

- Optimum performance by direct air intake

- The nozzles are outside the air flow

- 2 – step transmission with zero position

- Individual anti-drip nozzles swivelable and removable

- Optional nozzles

Additional equipment

- Electric remote control SC10/E2 up to E4 with 2 or 4 boom sections, solenoid valves and mechanical pressure regulator

- Electric remote control SC100/E2 up to E6 with 2, 4 or 6 boom sections, solenoid valves and electric pressure regulator, pressure indication in tractor cab

- Electric remote control SC100/E2 up to E6 with LCD display and touch screen, digital pressure and liquid level indicator, 2 – 8 boom sections available

- SPRAYDOS or SC100RC spray control computer, 2 to 8 boom sections possible (SC100RC is equipped with the same equipment as SC100CE, but only as a control device)

- Different tire options

- Double or triple anti-drip nozzles

- Injector nozzles

- Single-sided fan cover

(The tablet and tablet holder are not included).

Additional equipment

CLEVERSPRAYPRO Fully automatic control and spraying system

Upgrade your sprayer to the latest spraying technology with innovative sensors and control technologies,

smart applications and a real-time IoT platform.

- Control box

- Cable set

- Flow sensor

- Pressure sensor

- 2 speed sensors

- 2 distance sensors (SSC)

- Keypad

- SSC kit Section control

- Free access to the farmunited Cloud service

(data exchange, control, digital spray diary) - Regular software updates

Automatic free software updates

Technical data

Standard equipment

- Robust galvanized frame construction

- Adjustable axle

- Supplied with PTO shaft

- Fiberglass tank with optimal air inlet arrangement and integrated water tank for tank rinsing, switchable “spraying” / “rinsing” even if the tank is filled to maximum or partially, level indicator, agitator, two filling holes with filter, hand washing tank with drain cock.

- Filters: strainer, suction filter with automatic shut-off, pressure filter with quick cleaning, tool-free maintenance

- Diaphragm piston pump: Type “IDS1401” (140l./50 bar)

- Control devices: mechanical remote control type “MSC CD13”, central shut-off, boom section switch (two sections), pressure adjustment from the tractor cab, with pressure gauge.

Type |

Output

|

Pump

|

Nozzles

|

Empty weight

|

Row spacing min.

|

Row spacing max.

|

Cultural processing height max.

|

| KA24/1000-140 | 18./28.000 | 140/50 | 12 | 703 | 1.5 | 2.4 | 2.5 |

| KA24/1500-140 | 18./28.000 | 140/50 | 12 | 723 | 1.5 | 2.4 | 2.5 |

| KA24/2000-140 | 18./28.000 | 140/50 | 12 | 738 | 1.5 | 2.4 | 2.5 |

| KA28/1000-140 | 25./31.000 | 140/50 | 14 | 651 | 1.7 | 3.5 | 3 |

| KA28/1500-140 | 25./31.000 | 140/50 | 14 | 744 | 1.7 | 3.5 | 3 |

| KA28/2000-140 | 25./31.000 | 140/50 | 14 | 774 | 1.7 | 3.5 | 3 |

| KA32/1000-140 | 38./45.000 | 140/50 | 16 | 691 | 1.8 | 5 | 3.5 |

| KA32/1500-140 | 38./45.000 | 140/50 | 16 | 757 | 1.8 | 5 | 3.5 |

| KA32/2000-140 | 38./45.000 | 140/50 | 16 | 765 | 1.8 | 5 | 3.5 |

Video

If the video doesn’t play in your browser, click on the title of the video and watch it on YouTube.