Automated tree-specific blossom thinning

The Darwin SmaArt Camera System replaces the subjective estimation of the blooming strength with the eye with objective detection by camera. To do this, a camera in front of the thinning spindle detects the blossom density of each individual tree and passes on the data to the on-board computer in real time. Using a thinning algorithm, the computer then calculates the optimum spindle speed and controls the thinning unit. The thinning unit consist of a spindle on which six rows of cord bars are arranged that remove the blossom through rotation. The thinning intensity is controlled to a great extent by the spindle speed.

As an option, the system can be combined with a GPS receiver. Using the GPS system, it is possible to detect each individual tree and to assign the data, such as the number of blossoms and the spindle speed, to the tree and to compare it later with the yield data.

As a mechanical system, the Darwin SmaArt Camera System for automated blossom thinning can replace chemical or manual blossom thinning.

Characteristics

Simplified mechanical blossom thinning thanks to camera and intelligent speed control

Ensure profitable harvests with increased fruit quality and reduced labor bill!

- Controlled thinning that you see directly after execution

- Thins without chemical use

- Increase in fruit size and quality by increasing early sugar allocation to limited number of fruits

- Reduces biennial tndencies

- Fast travel speed ensures high treated area per hour

- Thinning can be performaed in all weather conditions

- Can be used for all current cultivars

The special camera captures the flowering density of each individual tree and relays the data in real time to the on-board computer.

In addition, the system can be combined with a GPS receiver to capture the location of each tree.

The high-performance on-board computer calculates the corresponding spindle speed from the data of the camera via a specially developed thinning-algorithm.

In the database in the on-board computer, the bloom density and the calculated spindle speed are then stored for each tree. The data can be retrieved from there at any time.

Technical Data

| Darwin | Darwin 150 | Darwin 200 | Darwin 230 | Darwin 250 | Darwin 300 |

| Working height | 1.475 mm | 1.935 mm | 2.245 mm | 2.395 mm | 2.850 mm |

| Working speed | 6 – 18 km/h | ||||

| Spindle rpm | 150 – 450 min1 | ||||

| Area perfromance | 1,5 – 2,5 ha/h | ||||

| String lenght | 600 mm | ||||

| String bars | 18 | 24 | 30 | 30 | 36 |

| Dimensions in mm (W/D/H) | 1.820/1.400/800 | 2.285/1.400/800 | 2.580/1.400/800 | 2.740/1.400/800 | 3.200/1.400/800 |

| Weight | 130 kg | 138 kg | 142 kg | 145 kg | 152 kg |

| Required oil quantity | 25 l/min | ||||

| Max. working pressure | 210 bar | ||||

| Mounting | Mounting to the front right side with or without front hydraulic system | ||||

| Manual sides shift | 595 mm | ||||

| Hydraulic side shift | 400 mm | ||||

Equipment variants

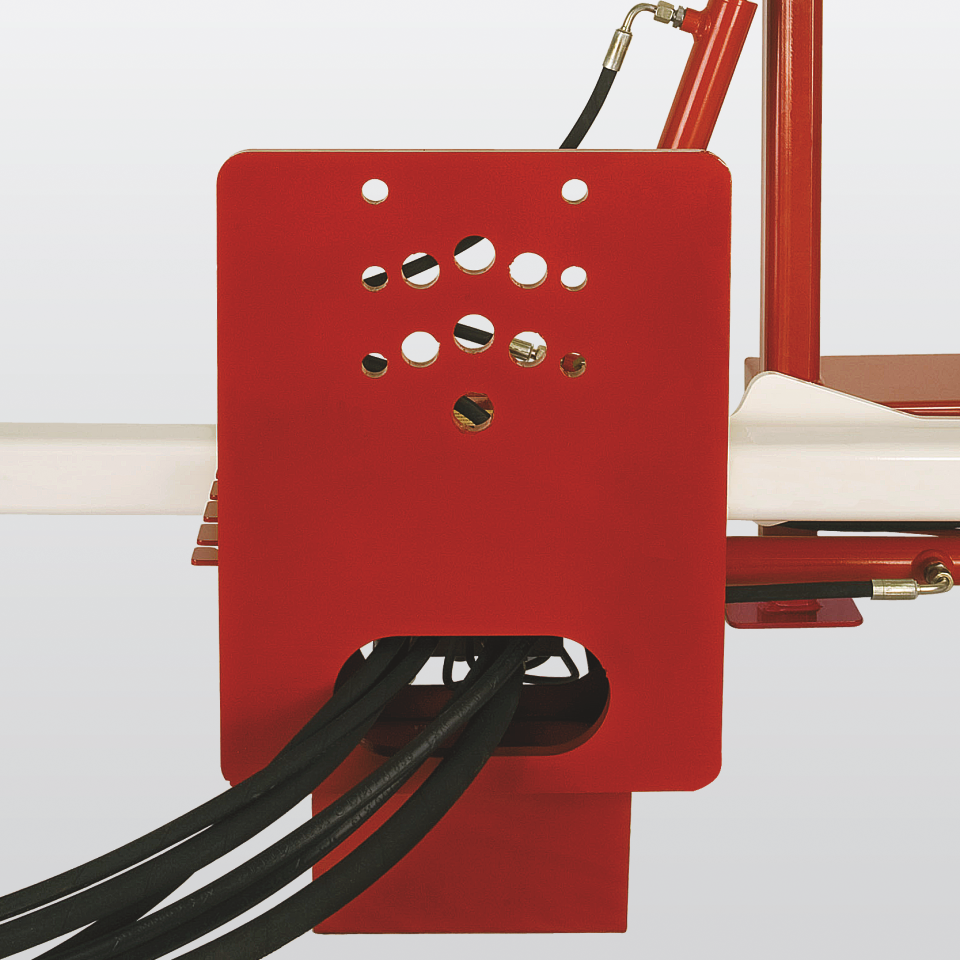

Mounting device front plate

For mounting without a front hydraulic system.

The holes are available for the most common tractors, otherwise the mounting plate has to be adapted individually.

Mounting device front hydraulic

For mounting on the (3 – point hitch) front hydraulic, for category I and II.